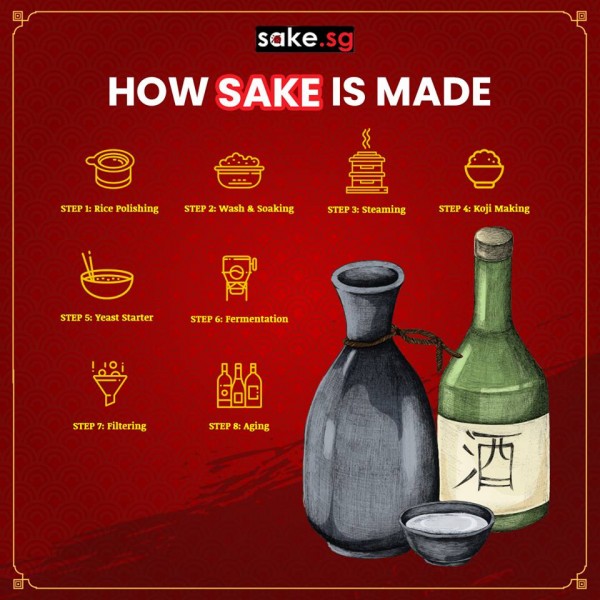

Let’s tackle some myths about Sake… How is Sake made?

Many thought that sake making is easy and simple but there are actually more processes into making a perfect sake.

1. Rice Polishing – Polishing too fast breaks kernels and over-heats the rice, so this work must done slowy and gently

2. Washing & Soaking – The purpose of soaking the rice is simply to allow it to absorb the desired amoung of water, getting just the right amount of water is quite a tricky business.

3. Steaming – In order to make ideal koji (rice malt) and to ensure proper fermentation, the rice kernels must be steamed in a way that results in a firm outer surface and a soft inner core.

4. Koji Making – About 20% of the rice steamed eacg day is used to make koji (rice malt), which is needed to change rice starch into sugar. Koji strongly influences the flavor and quality of the sake, so great care is take during the two days required to make it.

5. Yeast Starter – Creating shubo or yeast starter, which is a highly concentrated yeast culture that is central to the fermentation process.

6. Fermentation – It is time to make the main fermentation mash, called “moromi”.

7. Filtering – After about 21 to 25 days, the moromi has reached about 18% alcohol content, the fragrance and flavor have fully developed, and the sake is ready to be filtered.

8. Aging – Most sake is kept in tanks for between six months and two years, depending on the variety, and its regularly sampled to determine the best time for bottling and shipping.